Designing a valve as a confinement barrier

13 Feb 2017

-

Mark Henderson, Electron Cyclotron Section Leader

Fifty-six electron cyclotron waveguides will enter the Tokamak Building to deliver 20 MW of heating power to the ITER plasma. The challenge is that each one could act as a breach in building confinement during a catastrophic event such as an earthquake or fire. A special type of valve is under development with industry to improve confinement at each waveguide "point of entry."

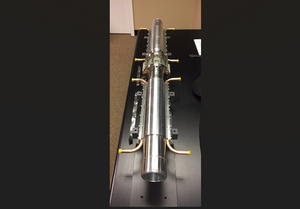

The electron cyclotron transmission lines feature multiple lines of aluminium waveguides (two small-scale prototypes are pictured). A new valve is under development with the aim of improving the confinement of the waveguide "points of entry" into the Tokamak Building and vacuum vessel.

The electron cyclotron heating system in ITER system heats the electrons in the plasma with high-intensity beams of electromagnetic radiation. The beams, produced by 24 powerful high-frequency (170 GHz) gyrotrons in the Radio Frequency Building, travel approximately 100 metres along transmission lines to the tokamak, where electron cyclotron launchers deliver them into the plasma.

The US Domestic Agency is responsible for 88 percent of the electron cyclotron transmission lines—including research and development, design, fabrication, and interfaces—while the ITER Organization is responsible for the installation of the transmission lines (12 percent).

The transmission lines feature multiple lines of aluminium waveguides with internal corrugations that can transmit up to 2 MWs per line for 3000 seconds, with a peak power density greater than 3 GW/m² at the centre. The transmission line has a circular cross section (ø63.5 mm) and has small grooves machined into its internal surface that minimize the power transfer losses to ≤ 10 percent.

Approximately 4 km of transmission lines will connect the 24 gyrotron sources in the Radio Frequency Building to 56 feeds with 10 types of waveguide components. The main interfaces include sources, launchers, buildings, port cells, water cooling, and auxiliary vacuum systems. There are 56 electron cyclotron waveguides entering into the Tokamak Building, and each could act as a breach in building confinement during a catastrophic event such as a large earthquake or fire.

To mitigate this risk a new valve is being developed to be installed at each "point of entry" of the waveguides—both in the Tokamak Building and the vacuum vessel port cells. The electron cyclotron teams at ITER and the US Domestic Agency are working with an outside contractor—the Swiss valve company VAT—to develop a new microwave component with the aim of improving the confinement of the waveguide penetrations.

The valve will not act as a vacuum barrier, but will form a confinement barrier limiting the flow of tritiated gas to <1mbar•litre/second from the galleries in the Tokamak Building to the Assembly Hall. There is limited space for these valves, as up to 24 waveguides are packed together in one penetration, so VAT has taken up the challenge of developing a new valve—the electron cyclotron isolation shutter valve. The shutter valve would swing a small plate into the gap of a waveguide to block, or isolate, its two sides.

The electron cyclotron teams at ITER and the US Domestic Agency are working with an outside contractor—the Swiss valve company VAT—to develop a new microwave component. Pictured, members of the team at VAT during a visit earlier this year.

Prior to embarking on the design, the ITER Organization and the electron cyclotron team from the US Domestic Agency have been collecting the specific requirements on the valve during various load conditions (i.e., fire, earthquake, increases in torus pressure, coolant leaks ...) and characterizing the valve requirements for each event. The requirements are then reviewed with VAT to ensure that existing technology can be extrapolated to this new component.

The action plan is to develop a prototype design of the isolation shutter valve with a manufacturing process and test plan defined and reviewed by ITER safety experts prior to "cutting metal." Then, the prototype will undergo testing for microwave propagation, vacuum compatibility and, most importantly, safety functions. If the valve passes all these tests, then the prescribed manufacturing and testing process is validated and we can proceed toward the final design review.

Recently, members of the US and ITER teams visited VAT near Buchs, Switzerland to review the various requirements, agree on the steps toward the finalizing the design and producing the first prototype, and review the qualification procedures including welding, testing and related FEM* analysis.

An existing ITER Organization-VAT contract will be amended in early 2017, with the aim of reaching the first prototype tests within a year.

* Finite Element Method: a computer model that simulates a large object in small pieces (or elements) and permits the propagation of forces to be represented.