In-vessel coils

Conductor qualified for manufacturing

17 Sep 2018

For magnet coils operating inside of the vacuum vessel, conventional insulation schemes are not an option. ITER will rely on mineral-insulated conductor technology for its ability to withstand large transient electromagnetic fields, high radiation flux, and high temperature. After a decade of development and intensive collaboration with industry and research institutes, the first manufacturing phase—qualification—was recently concluded.

On 1 August, the ASIPP team in China celebrated the successful manufacturing of the first 100-metre continuous length of copper tube. Single-piece tubes are important to avoiding joints in the coils.

The coils inside the ITER vacuum vessel are part of the overall plasma control system that ensures and maintains stable plasma operations. Two vertical stability coils will provide fast vertical stabilization of the plasma, while an array of 27 edge localized mode (ELM) coils will create resonant magnetic perturbations to magnetically control the plasma exterior in order to suppress potentially harmful power deposition on plasma-facing components.

The in-vessel coils will be mounted on the vacuum vessel wall, behind the blanket shield modules.

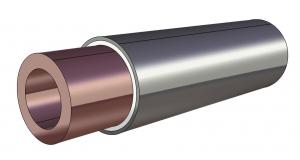

The backbone of both types of in-vessel coil is a non-superconducting mineral-insulated conductor, which consists of a stainless steel jacket, a layer of mineral insulation, a hollow copper conductor, and a central water cooling channel. The mineral layer—made of compressed magnesium oxide (MgO) powder—provides electrical insulation between the jacket and the conductor, as well as thermal conduction and structural support for the copper conductor.

"The ITER Organization has managed substantial design and R&D work over the last 10 years to finalize the design of the mineral-insulated conductor and develop suitable manufacturing procedures and techniques to ensure manufacturability," says Anna Encheva, the ITER engineer in charge of the in-vessel coil conductor. "With this work behind us we are ready to enter the series manufacturing phase. However, as most in-vessel coil components cannot be based on existing industrial solutions, we have organized a two-phase process—first conductor manufacturing qualification, then fabrication."

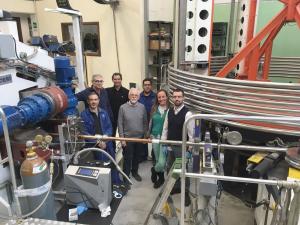

Long conductor manufacturing was also successfully demonstrated by the ICAS consortium in Italy in March 2018. These qualification milestones bring to an end a 10-year R&D program managed by the ITER Organization to finalize the design of the mineral-insulated conductor and develop techniques to ensure manufacturability.

Conductor manufacturing contracts were signed in early 2017 with two suppliers—the Italian Consortium for Applied Superconductivity (ICAS) and the Institute for Plasma Physics, Chinese Academy of Science (ASIPP)—for the qualification phase.

One of the most challenging fabrication activities has been to manufacture long, single-piece copper tubes required by the ITER design in order to avoid having joints in the coils. The manufacturers had to demonstrate suitable techniques and equipment, as well as compliant mechanical properties in the final product.

The mineral-insulated conductor developed for ITER uses a layer of compressed magnesium oxide (MgO) powder that provides electrical insulation between the jacket and the conductor, as well as thermal conduction and structural support for the copper conductor.

Also, although MgO insulation is used widely in industry for small applications (fire-proofing industrial cables and diagnostic cables, for example) the quantities required for the ITER in-vessel coil conductor are without precedent. The suppliers have had to develop robust quality control to keep impurity content in the insulation at a very low level (important to maintaining excellent resistance) and to limit the absorption of moisture (as a very hygroscopic material, MgO easily absorbs moisture from air).

"Other challenges in the manufacturing process result from the stiffness of the conductor, which makes assembly activities difficult, and the strict dimensional tolerances required by ITER," explains Encheva. "These tolerances are driven by both the structural integrity requirements of the final coil and the tight space limitations in the in-vessel environment."

The qualification phase has now been concluded successfully by both suppliers, as confirmed at recent in-factory manufacturing readiness reviews during which the review panel assessed the results of the qualification phase as well as the availability of resources and equipment for series production.

One supplier will be selected to manufacture a total length of approximately 5 km of conductor during the series manufacturing phase. The ITER Organization expects to award the contract by the end of this year.