Blanket Test Program begins

From 3-6 June, the ITER Blanket Progress Meeting took place in Prague, Czech Republic. The meeting represents an important milestone towards the realization of the agreed roadmap towards the design and procurement of the ITER blanket.

The ITER blanket, consisting of 440 individual modules, each measuring 2 by 1,5 meters and weighing up to 4.5 tons, is one of the most critical and technically-challenging components in ITER: Together with the divertor it directly faces the hot plasma. Its objective is to maintain a clean plasma during operation whilst shielding the vacuum vessel and superconducting coils from excessive heat and neutron fluxes.

Six of the seven ITER parties requested to be involved in the ITER blanket procurement as they consider it to be an essential technology which is important for the next steps towards fusion energy. "Because of the critical nature of this component, the ITER blanket (as well as the divertor and the superconducting materials for the coils) is one of three procurement packages for which the parties must 'qualify' prior to being allocated the procurement package," explains Michael Pick, Division Head of the ITER In-Vessel Components.

For the "qualification," each Domestic Agency must demonstrate, well in advance of the assumed start of the procurement, its technical capability to carry out the procurement with the required quality, and in an efficient and timely manner. This is achieved through the manufacturing and testing of specific mock-ups and/or prototypes according to a previously defined "Pre-qualification Program" which includes detailed specifications, schedules and acceptance criteria.

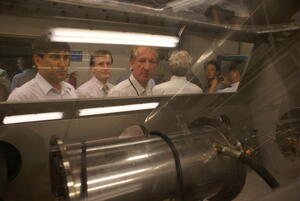

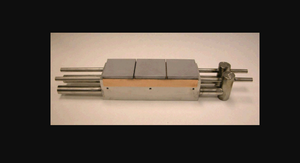

The heat flux and fatigue tests are carried out in the US and in the EU; the electron beam facility in Sandia National Laboratories in Albuquerque, New Mexiko, USA, the EU fatigue tests are done in the recently completed thermal radiation facility BESTH near Prague, Czech Republic, and the EU high heat flux tests will be carried out at the electron beam facility JUDITH in Jülich, Germany. The tests have begun at Sandia on two mock-ups, one from the EU and one from the US, with the aim to reach 12 000 cycles at 0.875 MW/m2. At the moment more than 7000 cycles have been successfully completed. Tests at the BESTH are just about to begin where the aim is to reach 12 000 cycles at 0.625 MW/m2.

A second set of tests are planned during which similar tests will be carried out on semi-prototypes. These are full scale (but not full size) components which will incorporate all the main technologies required for the manufacturing of the modules.

After the ITER Design Review it was decided to re-visit the ITER blanket design in-order to improve the power handling capabilities and some of the remote handling aspects of the cooling water attachment. Also, the possibility to use the blanket modules to start-up and shut-down the plasma was to be investigated. "If it turned out that this were indeed feasible, it would contribute to a simplification of the design and to cost savings," says Michael Pick.

Due to the lack of design resources within ITER, a plan was developed allowing the 440 modules to be designed and tested jointly by the ITER Organization and the Domestic Agencies of the parties involved. The plan was presented and accepted by all the parties in January 2008 in the form of a "Common Understanding on the Design and Procurement of the ITER Blanket First Wall Modules and Blanket Shield Modules." This plan describes the strategy toward the completion of the designs and includes the qualification stages and the associated schedule.

The plan hinges on the fact that the IO, together with individuals from each of the parties will develop and design so-called generic blanket modules. "These will incorporate all the design solutions into two or three modules and form the basis on which all other module designs can be developed," Pick explains. "Also included in the plans is the required benchmarking of all the relevant tools to complete the designs in the parties, namely the codes and methodologies to be used for the calculation of the electro-mechanical loads, the halo current loads, the neutronics, thermo-hydraulics, and the structural loads."

The meeting in Prague was thus called to update all the parties on the overall status of the ongoing work on the development of the generic modules, the progress in the qualification program, the benchmarking process, and to plan and confirm the next steps.