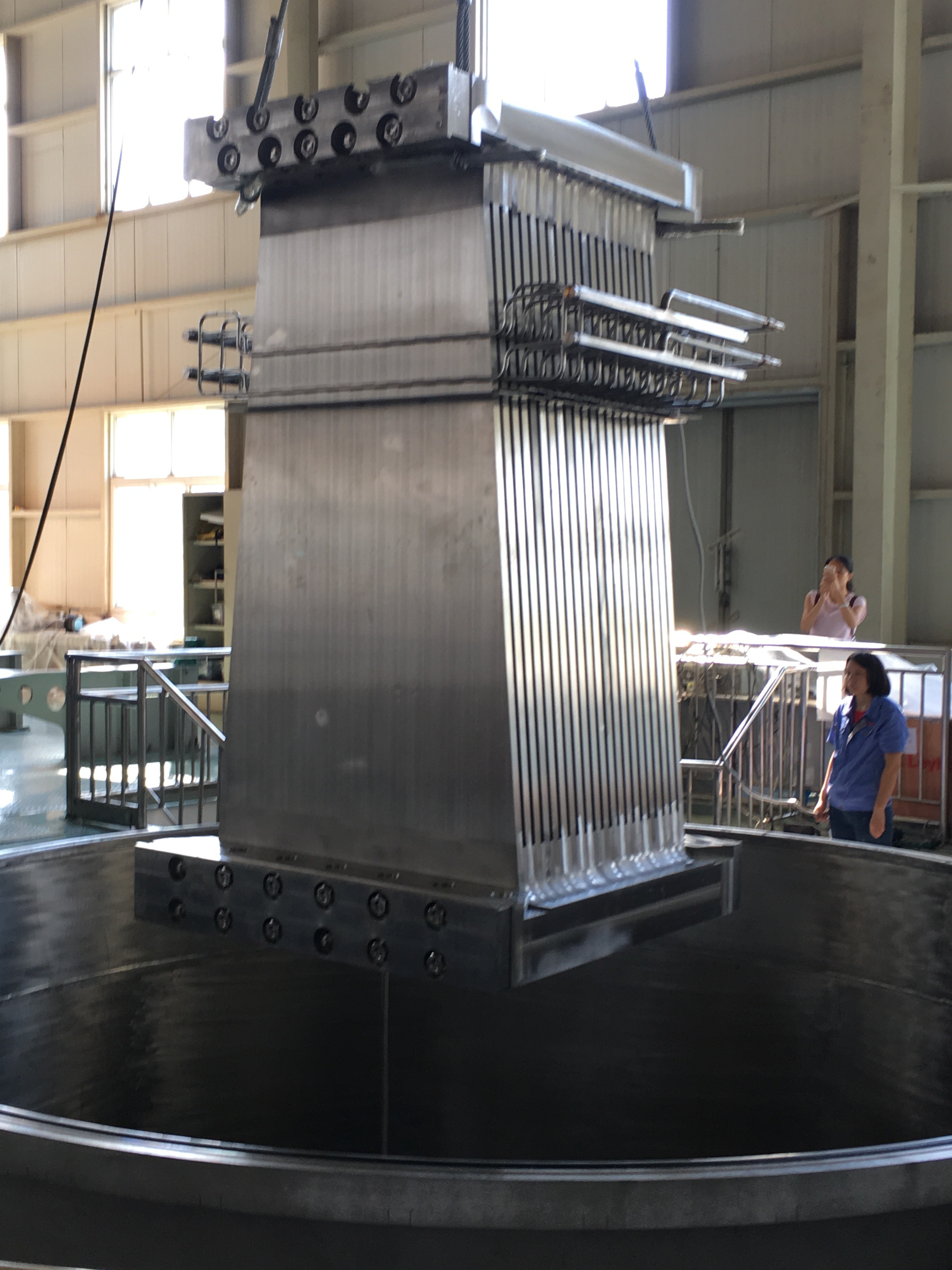

This push and pull represented a severe design challenge for engineers, requiring many years of prototyping, load analyses and testing. Working from an ITER Organization design, engineers in China worked closed under the coordination of the ITER Magnet Division, the Chinese Domestic Agency and SWIP. In 2013, an

engineering test platform was built at SWIP to apply the loads—and load combinations—that are expected during operation at ITER on these qualification mockups.

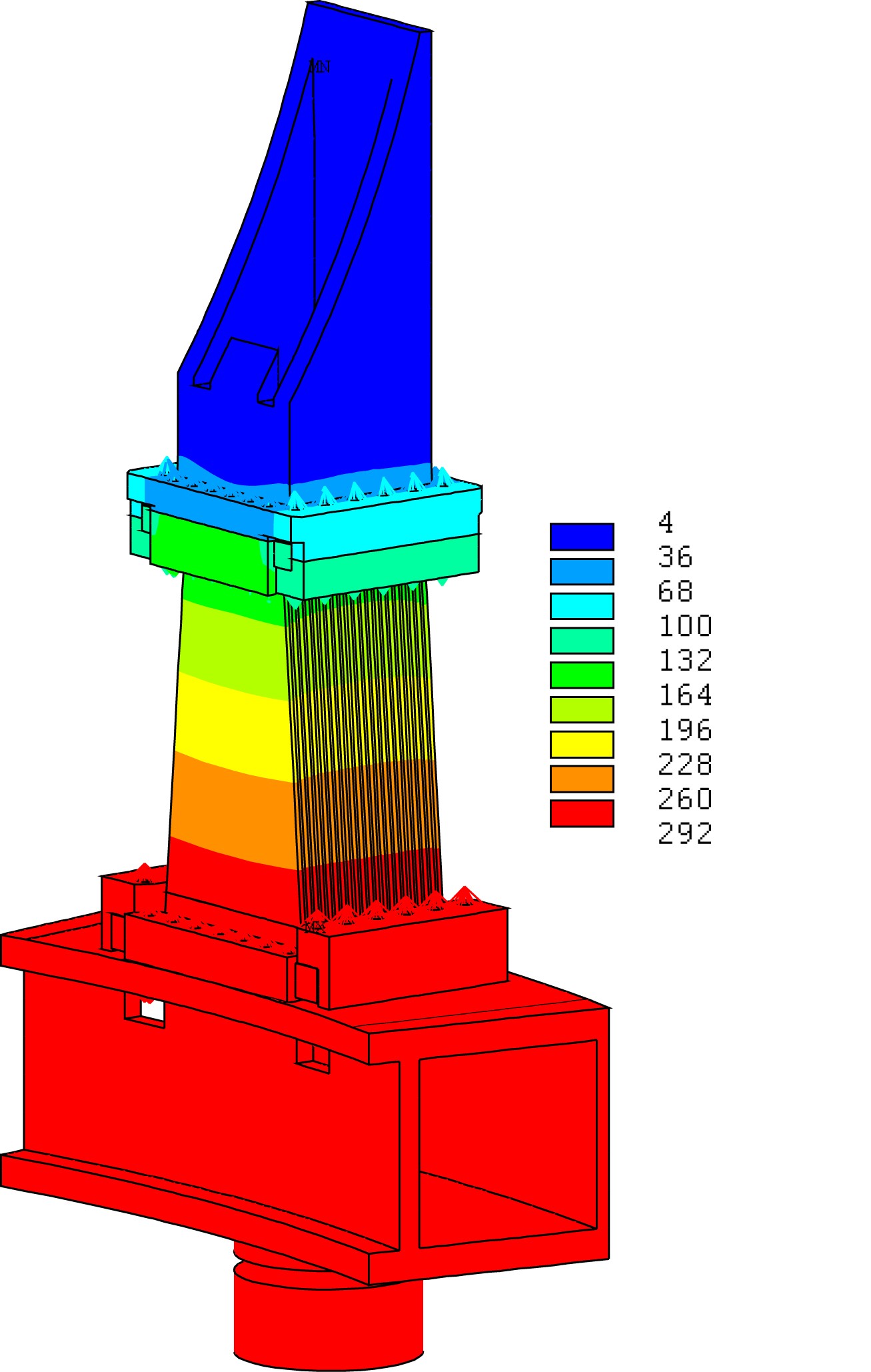

The solution is a mix of flexibility and rigidity—a sandwich of 21 flexible plates, 30 mm thick, divided by spacers that are pre-assembled and clamped together at bottom and top with pre-stressing bars and tie rods; these bars and rods are pre-tensioned with stud tensioners. Active cooling provided at two-thirds of the height of the assembly smooths the transition between the toroidal field magnets at 4 K on top and the room temperature at the base of the structure.

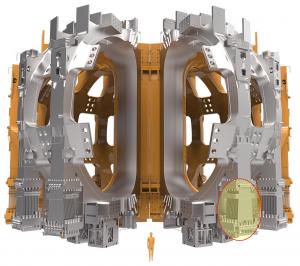

"The gravity support will have to be able to resist the toroidal and vertical motion and related forces of the toroidal field coils during the Tokamak operation, but also allow their radial motion during cooldown and warmup," explains Cornelis Beemsterboer, structural engineer for the Magnets Division and technical responsible officer for the different magnet supports. "At the same time each vertical plate is designed to support 27 tonnes of the overall gravity load. Analysis has shown that the design meets all requirements for both room and operating temperature conditions."

The first production module in China has performed well in factory acceptance tests, including a thermal shock test, helium leak tests on the active cooling pipes, and pressure tests. Still to come is the final assessments on the final applied pre-loading of the bolts. "The gravity supports are impossible to replace and we need to be sure that the bolts will keep the vertical plates together for the full duration of ITER operation," emphasizes Beemsterboer.

The full set of gravity supports is expected on site in mid-2019 for installation in the machine on the pedestal ring ahead of the toroidal field magnets. China is also manufacturing other magnet supports for the poloidal field and correction coils—in all, more than 400 tonnes of equipment.