Welding filler material alone is not sufficient for filling the gaps, however. Before welding operations can commence, the spaces are closed off by 60-millimetre-thick bands of steel called "splice plates" that will be positioned, one after the other, by a special tool developed by ENSA.

Fifteen inner and 16 outer plates need to be inserted into the gaps between sectors. "We will manufacture them roughly, with extra width, thickness and length, and then reverse-engineer them by precise custom machining to the exact dimensions of the gap," explains Brian Macklin, project manager in the Tokamak Assembly Division and the original responsible officer for the ENSA contract.

Using an ultra-precise laser survey (

see video here), each gap will be mapped and rendered as a 3D drawing. The data will then be fed to a high-precision tool that will machine the final plates to the exact dimension and topography of the gap. With the plates in place, the distance between the sectors will be reduced to half a millimetre.

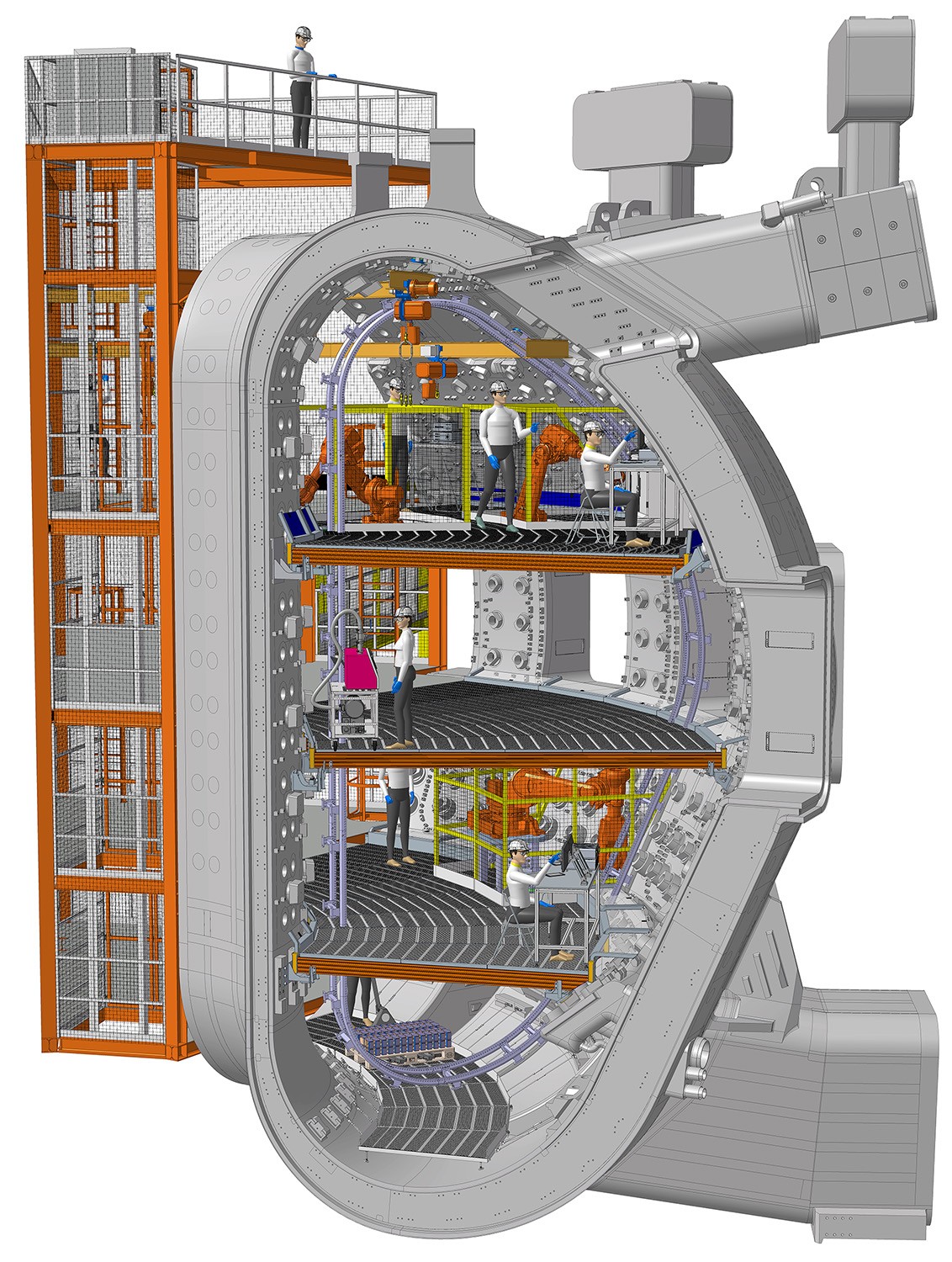

Three large welding robots will then enter the scene, introducing welding heads into the gaps at different locations around the vessel; by operating them simultaneously, the shrinkage caused by the welding process is distributed all around the D-shaped section of the sectors.

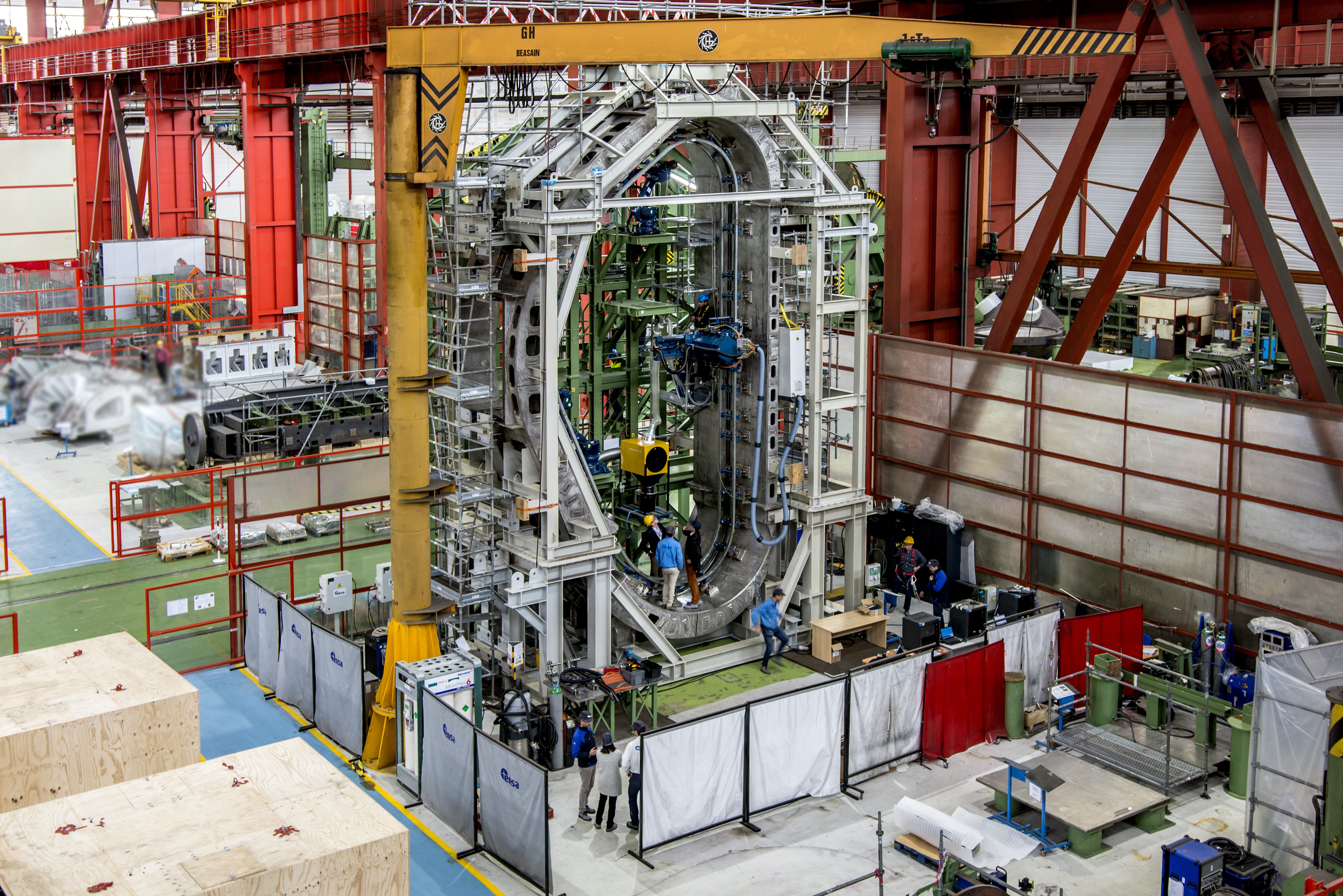

"We have now reached the final stage of tool and procedure qualification on the mockup," explains Frantz de la Burgade, ITER group leader for sector assembly and the current responsible officer for the ENSA contract. "Half of the splice plates have been fully welded on the outer shell of the sector and the smoothing of the welds by a weld cap machining tool is ongoing. There are still a few parameters to streamline, such as assessing the importance of the weld shrinkage or detailing a few remaining interfaces with the vessel for the real work."

Amidst the din of ENSA's Special Projects' workshop, Brian Macklin, Frantz de la Burgade and Alex Martin, the ITER group leader for vacuum vessel engineering, observe, question, discuss, and take notes and measurements. Like directors on a set, they make certain that the acts are in conformity with the scripts. The dress rehearsal is now almost over; the actual production should premiere at ITER in the autumn of 2020.

More technical information can be found in the image gallery below.