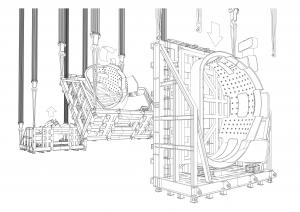

Lift and tilt

It has been seven months since the Korean Domestic Agency delivered vacuum vessel sector #6 to the ITER construction team. After final acceptance tests in September, the assembly teams worked to complete a number of installation tasks while the component was horizontal.

During this period, for example, assembly contractors installed 120 magnetic sensors*. "A number of steps were involved," says Yunxing Ma, from ITER's In-Vessel Diagnostics Section. "The metal cases containing the magnetic sensors were first welded to the bosses (four per sensor); then, the signal cables were routed and girded. We carried out electrical tests to verify signal continuity, and metrology to measure the as-installed positions of the sensors with respect to the datum." In a later phase, when the sector is in the Tokamak pit, the cables will be connected with the backend signal transmission network in order to link the sensors to the data acquisition system.

The ITER Newsline will have a full report.

* Densely distributed and spanning two full poloidal arrays, these sensors will deliver high-resolution magnetic field measurements across the entire vacuum vessel, providing key data for reconstructing the "magnetic field map"—critical information for plasma operation.