you're currently reading the news digest published from 17 Jan 2022 to 24 Jan 2022

featured3

of-interest1

press10

featured

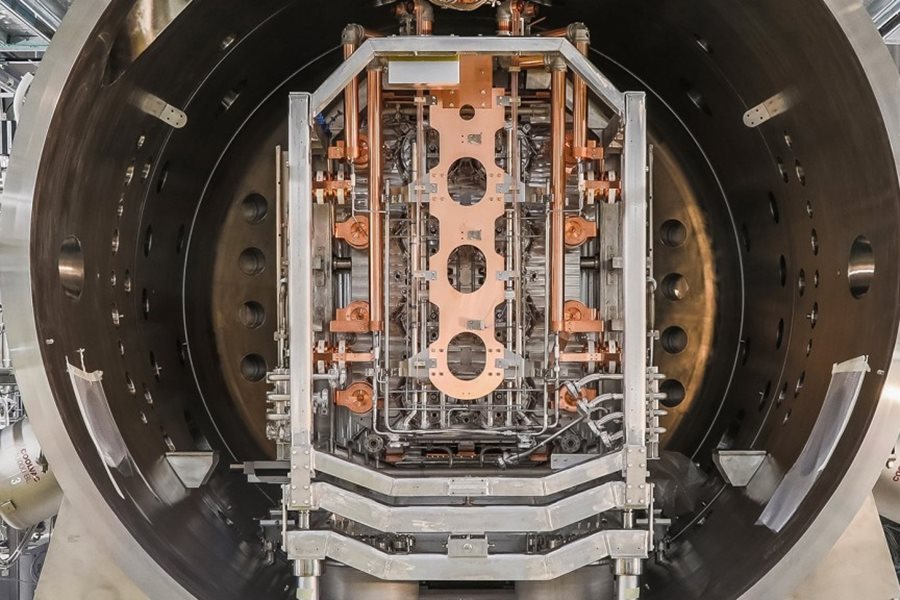

Neutral Beam Test Facility | Lessons learned from SPIDER, a full-size negative ion source

SPIDER finished its first test campaign in late November 2021 and is now entering an upgrade phase. During this time, the testbed will be shut down for about one year to make changes based on what was learned during the campaign. Since 2018, tests have been run on the SPIDER experiment at the Neutral Beam Test Facility (NBTF) in Padua, Italy, to further understand the physics and to validate the designs of the neutral beam injection systems that will operate at ITER. The NBTF is hosted by the Consorzio RFX and funded by the ITER Organization, the European Domestic Agency and the Italian government. The European, Japanese and Indian Domestic Agencies are all contributing components. SPIDER is one of two separate testbeds that will ultimately be installed at the facility. The second, called MITICA, will be a full prototype of a heating neutral beam injector on the same scale as the injectors that will heat the plasma at ITER. The core of both test beds is the ion source, where the negative ions are generated in an ionized gas (plasma) and extracted from the plasma in the form of thousands of individual beamlets by means of multi-aperture electrodes (dubbed 'grids'). The ion source is almost the same for both experiments, but MITICA will have an additional five grids to accelerate beams to 1 MeV—ten times the energy of SPIDER. While SPIDER lacks the power density of MITICA, it is still a full-size negative ion source that makes it possible to study the production of high-current negative ion beams before assembly of the high voltage equipment that will be used in MITICA and to anticipate part of the experimental program. MITICA, in fact, is not expected to start experiments until late 2024. 'Our job is to observe what happens at the Neutral Beam Test Facility to learn things that can be used to improve the design of the neutral beam systems for ITER,' explains Pierluigi Veltri, Neutral Beam Coordination Officer. 'We have already done this for some sub-systems. For example, during testing, imperfections were discovered in a magnetic field activated within the ion source. To fix the problem, the position of some conductors was changed to optimize the magnetic field topology. We immediately took this new design and implemented it in the diagnostic neutral beam ion source, which like SPIDER, operates at 100 kV and which will be used to diagnose the properties of the ITER plasma.' New discoveries 'We started testing SPIDER in 2018,' says Veltri. 'In the beginning the idea was to operate for one year and then do upgrades. But then we extended the campaign to three years.' Because SPIDER is both the largest negative ion source in the world and the only one running in a large vacuum, testing often yields discoveries that require changes. One example of this is that after a few months of testing it became clear that an enhanced vacuum system would be needed. The long procurement time of the new vacuum system was one of the reasons the campaign was prolonged. It the meantime, the team implemented a workaround that led to some surprising observations. The experiments were modified so that instead of opening all 1,280 apertures (each about 1.5 cm in diameter) on the first grid, some were covered up. As a result, individual beamlets passed through only some of the holes. 'When you open all the apertures, you can't tell any of the beamlets apart,' explains James Zacks, Neutral Beam Test Facility Scientist. 'But the separate beamlets allowed us to see how tightly, or broadly, the beams diverge. We are now trying to understand how to get the beams as narrow as possible so we can avoid heating the sides of the beam line, which is a waste of power. We want to concentrate that power as much as possible.' Another major achievement occurred relatively late in the testing campaign when cesium operation was tested in May 2021. Cesium is used as a catalyst to get negative ions out of hydrogen using a technique that has been known for years but never tested on a large-scale ion source. 'We demonstrated that cesium injection was effective, even with reduced source power,' says Veltri. 'We went from an extracted current density of 20 to 30 amperes per square metre all the way up to 170 amperes per square metre.' Changes and upgrades 'One of the big changes we're making is to replace the old-style radio frequency tetrode oscillators with solid state amplifiers,' adds Zacks. 'Ion sources are powered by a radio frequency power supply. When MITICA was being designed, tetrode oscillators were the standard but now there are better options. We have more confidence in solid state, which will allow us to resolve some of the issues associated with the tetrodes.' 'The new solid state power supply will make it possible to achieve the full power of the ion source, which is 800 kW,' adds Veltri. 'Until now we could only operate at half that power.' 'The additional time has also allowed us to improve some of the diagnostics on SPIDER,' says Zacks. 'Because the heating neutral beams will be run in a tokamak, we will be very limited in what we can do with diagnostics at ITER. However, SPIDER is not constrained by a nuclear environment and complex physical access. That gives us the opportunity to add the diagnostics to the testbed to better understand the physics.' The upgrades that will be installed within the next year are expected to allow testing at full intensity and for the required duration—1000 seconds for hydrogen, and one hour for deuterium. 'We learned a few things and are now making several big upgrades,' explains Zacks. 'That's how engineering often works.'

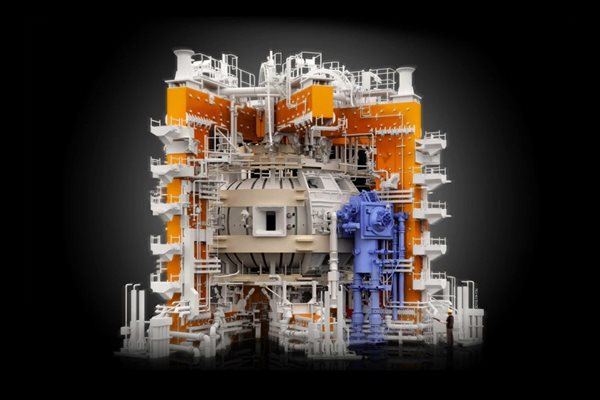

Manufacturing | Korea completes a third vacuum vessel sector

A third 40-degree sector of the ITER vacuum vessel has exited the Hyundai Heavy Industries production line in Ulsan, Korea. Sectors representing one-third of the complex, double-walled chamber that will house the 150-million-degree ITER plasma have been produced in Korea and a fourth sector is in the final stages of manufacturing (> 90 percent complete). Sector #8, which will ship from Korea this week, will follow the path marked out by Korean sectors #6 and #1(7)—first travelling to ITER by boat, barge and road ... then passing site acceptance testing ... and finally undergoing a series of pre-assembly activities in the Assembly Hall (first in its horizontal shipping position, then once vertical). The final destination for each sector is the ITER Tokamak pit, where the sectors will be supported by in-pit tooling until they are joined by welding. At Hyundai Heavy Industries, vacuum vessel series production activities have been underway since the first cutting operation took place on sector #6 in 2012. (Sector #6 was delivered to the ITER Organization in 2020.) With such long manufacturing lead-time, the teams did not waited for one sector to be completed in order to begin on another; instead, the sectors were brought along side by side in tight sequence. Along the way, the Korean Domestic Agency has worked closely within the Vacuum Vessel Project Team with the other Domestic Agencies involved in the procurement of the vacuum vessel (Europe: five sectors; India: in-wall shielding; Russia: all upper ports). In the gallery below, see vacuum vessel sector #8 during final D-shape assembly, inspection and packing. In next week's ITER Newsline, we'll include a picture of the 440-sector loaded on the boat that will deliver it to Fos-sur-Mer, France.

On-site coil manufacturing | Two more to go!

In the European winding facility on site, two large poloidal field coils have already left the manufacturing line. Two others are currently advancing through the complex, multistage fabrication process that begins with the unwinding of conductor spools and ends with a fully tested component ready for assembly. The first two coils were 17 metres in diameter—poloidal field coil #5 (finalized in April 2021), and poloidal field coil #2 (finalized in December 2021). Two significantly larger coils (⌀ 24 m) are presently the focus of the European team on site—the 'middle coils' of the six ring-coil suite (PF3 and PF4). At the south end of the vast manufacturing facility, a 16-tonne spool is lifted out of its transport frame and inserted into the bespoke tool that will unwind the 900 metres of jacketed conductor it contains. The operation is the first act of the coil fabrication process and it has been repeated 56 times already since the first 'dummies' were produced back in 2016. Procured by China and manufactured by the Institute of Plasma Physics of the Chinese Academy of Science (ASIPP), the conductor is destined for poloidal field coil #3 (PF3). In order to form the 'double pancakes' that each coil is built from, conductor lengths are fed from two spools simultaneously ("two-in-hand" winding) to be unwound, straightened, cleaned, curved to the correct degree and wrapped in insulating fibre tape. PF3, which will be assembled from a stack of 8 double pancakes, requires approximately 14 kilometres of cable. The double pancake windings are then hardened into a rigid assembly by vacuum pressure impregnation with epoxy resin. Three double pancakes for PF3 are currently at various stages of resin impregnation, while a fourth is still on the winding table. Further down the assembly line, eight double pancakes for poloidal field coil #4 (PF4) have already been stacked. The teams are preparing the coil for ground insulation, an operation which consists in wrapping the stack with nine successive layers of glass-Kapton tape that insulate it electrically. The delicate wrapping operations are done by hand, as the helium inlets situated at regular intervals do not allow the automation of the process. Following ground insulation, the coil pack will undergo impregnation, further assembly (clamps, protection covers, pipes...) and finally cold testing. When PF4 and PF3 are delivered to ITER, in mid-2023 and mid-2024 respectively, Europe will have completed its poloidal field coil procurement package.¹ ¹ Europe is responsible for poloidal field coils #2, #3, #4, #5 and #6. (PF1 is procured by Russia.) Due to schedule constraints and space availability, PF6 was manufactured in China under a European contract.

of-interest

JET: Hello #100,000

Since its inauguration in 1983 in the presence of Her Majesty Queen Elizabeth II, the European tokamak JET has cemented its reputation as "one of the most important machines in the history of fusion energy research," according to Ian Chapman, CEO of the UK Atomic Energy Authority. On 18 January 2022, the machine ran its 100,000th plasma pulse. JET, for Joint European Torus, is the focal point of the European fusion research program, designed to study fusion in conditions approaching those needed for a power plant. It is the only experiment that can operate with the deuterium-tritium fuel mix that will be used for commercial fusion power (and in ITER). In 1997 JET successfully produced a world record 22.5 megajoules of fusion energy and 16 megawatts of fusion power during the first dedicated deuterium-tritium experiments, proving large amounts of power can be produced from fusion. In 2011 JET was equipped with a new ITER-like inner wall made of beryllium and tungsten metals, enabling scientists to develop plasma scenarios that resemble as closely as possible those planned for ITER, investigate the interaction of the plasma with wall materials, and study the accumulation of tungsten from the wall in the plasma core. In 2021, JET carried out a second full-power run of experiments using deuterium and tritium. Stay tuned: the results from these experiments will be announced in early February 2022. The JET facilities located at the Culham Centre for Fusion Energy (CCFE) in Abingdon, Oxfordshire UK, are collectively used by all European fusion laboratories under the EUROfusion consortium. About 350 scientists from EU countries (plus Switzerland, the UK and Ukraine), and more from around the globe, participate in JET experiments each year. CCFE is responsible for operating the facility for fusion researchers and for maintaining and upgrading it. This work is carried out under a contract between the European Commission and the UK Atomic Energy Authority (CCFE's operator). The ITER community congratulates the JET team on its 100,000th pulse!